– Instantaneous hot water for commercial dishwashers

– Stainless steel construction ensures long life

– 4 to 54 kW

– Convenient for under-counter installation

Specifications

| BOOSTER MODEL NUMBERS, kW RATINGS AND MAX. AMPERAGE DRAW |

|||||||||||

| Model Number |

kW | Btu/Hr | TankCapacity U.S. Gal |

U.S. Gal./Hr 40ºF Rise |

Maximum Amperage Draw (A) | Approx. Shipping Weight |

|||||

| Single Phase | Three Phase | ||||||||||

| 208 | 240 | 208 | 240 | 480 | 600 | ||||||

| 304B | 4 | 13,649 | 4.27 | 41 | 19.2 | 16.7 | – | – | – | – | 60 LBS |

| 305B | 5 | 17.062 | 4.27 | 52 | 24.0 | 20.8 | – | – | – | – | 60 LBS |

| 306B | 6 | 20,474 | 4.27 | 62 | 28.8 | 25.0 | 16.6 | 14.4 | 7.2 | 5.8 | 60 LBS |

| 309B | 9 | 30,711 | 4.27 | 93 | 43.3 | 37.5 | 25.0 | 21.6 | 10.8 | 8.7 | 60 LBS |

| 312B | 12 | 40,948 | 4.27 | 124 | 57.7 | 50.0 | 33.3 | 28.8 | 14.4 | 11.5 | 65 LBS |

| 315B | 15 | 51,185 | 4.27 | 156 | 72.1 | 62.5 | 46.4* | 40.2* | 20.1* | 16.1* | 65 LBS |

| 318B | 18 | 61,422 | 4.27 | 187 | 86.5 | 75.0 | 54.6* | 47.3* | 23.7* | 18.9* | 70 LBS |

| 424B | 24 | 81,895 | 5.80 | 249 | 115 | 100 | 66.5 | 57.7 | 28.8 | 23.1 | 70 LBS |

| 430B | 30 | 102,369 | 5.80 | 311 | 144 | 125 | 83.2 | 72.1 | 36.0 | 28.8 | 75 LBS |

| 436B | 36 | 122,843 | 5.80 | 373 | 173 | 150 | 100 | 86.5 | 43.3 | 34.6 | 75 LBS |

| 439B | 39 | 133,068 | 5.80 | 405 | 188 | 163 | 108 | 93.7 | 48.8* | 39.1* | 80 LBS |

| 545B | 45 | 153,554 | 5.80 | 467 | 216 | 188 | 125 | 108 | 54.1 | 43.3 | 90 LBS |

| 554B | 54 | 184,264 | 5.80 | 560 | 260 | 225 | 150 | 130 | 64.9 | 51.9 | 90 LBS |

| SPECIFY MODEL NUMBER, VOLTAGE AND EITHER 1 OR 3 PHASE WHEN ORDERING |

|||||||||||

| * Delta connection (unbalanced load) amperage of high leg indicated. | |||||||||||

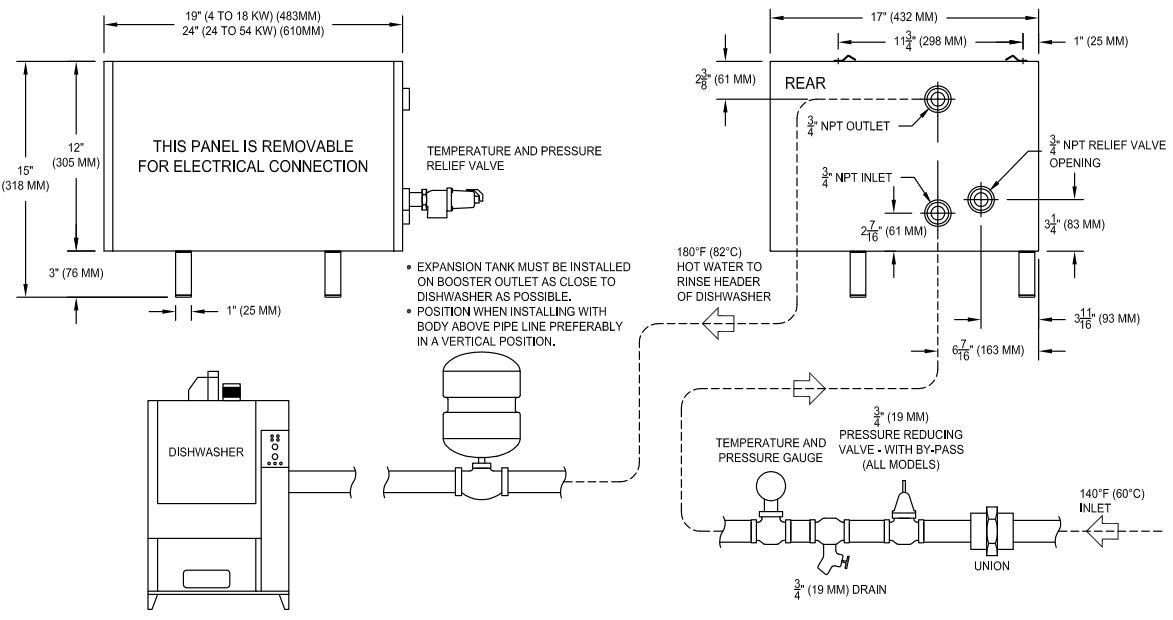

Dimensions and Piping

| Maximum Operating Pressure: | 130 PSI | |

| Maximum Operating Water Temperature: | 210ºF | |

| Water Capacity in Boiler (4-18 kW): | 4.27 US Gallons | |

| Water Capacity in Boiler (24-54 kW): | 5.80 US Gallons | |

| Inlet and Outlet Pipe Size: | 3/4” NPT |

– Hanging brackets are for under-counter suspension if specified with the order

Water Temperature Recovery:

Booster Heater Water Recovery Formulas:

GPH = 415 x kW / (Temp. Rise [°F]), LPH = 874 x kW / [Temp. Rise [°C])

Water Temperature Recovery Table in GPH (LPH):

| Model | kW | 30 º F (17 º C) | 40 º F (22 º C) | 50 º F (28 º C) | 60 º F (33 º C) | 70 º F (39 º C) | 80 º F (44 º C) | 90 º F (50 º C) |

|---|---|---|---|---|---|---|---|---|

| 304B | 4 | 55 (208) | 41 (155) | 33 (125) | 28 (106) | 24 (91) | 21 (79) | 18 (68) |

| 305B | 5 | 69 (261) | 52 (197) | 41 (155) | 34 (129) | 29 (110) | 26 (98) | 23 (87) |

| 306B | 6 | 83 (314) | 62 (235) | 50 (189) | 41 (155) | 35 (132) | 31 (117) | 27 (102) |

| 309B | 9 | 124 (469) | 93 (352) | 75 (284) | 62 (235) | 53 (200) | 47 (178) | 41 (155) |

| 312B | 12 | 166 (628) | 124 (469) | 100 (379) | 83 (314) | 71 (269) | 62 (235) | 55 (208) |

| 315B | 15 | 208 (787) | 156 (590) | 125 (473) | 104 (394) | 89 (337) | 78 (295) | 69 (261) |

| 318B | 18 | 249 (942) | 187 (708) | 149 (564) | 125 (473) | 107 (405) | 93 (352) | 83 (314) |

| 424B | 24 | 332 (1256) | 249 (942) | 199 (753) | 166 (628) | 142 (537) | 125 (473) | 111 (420) |

| 430B | 30 | 415 (1571) | 311 (1177) | 249 (942) | 207 (783) | 178 (673) | 156 (590) | 138 (522) |

| 436B | 36 | 498 (1885) | 373 (1412) | 299 (1132) | 249 (942) | 213 (806) | 187 (708) | 166 (628) |

| 545B | 45 | 622 (2354) | 467 (1767) | 373 (1412) | 311 (1177) | 267 (1010) | 233 (882) | 207 (783) |

| 554B | 54 | 747 (2827) | 560 (2120) | 448 (1695) | 373 (1412) | 320 (1211) | 280 (1060) | 249 (942) |

Booster Heater Cross Reference Chart

All sizings are based on dishwasher manufacturer ratings. Confirm the booster size with dishwasher manufacturer before ordering it. Allied Technologies Company is not responsible for incorrect sizing of applications.

| DISHWASHERS | BOOSTER HEATER CROSS REFERENCE CHART |

40ºF RISE |

70ºF RISE |

| ADAMATION | CSL-1390, CA-2, CA-3, CA-4 |

439B | (2) 436B |

| CA, CA-1 | 554B | (2) 545B | |

| BLAKESLEE | UC-21 | 306B | 312B |

| D-8 | 309B | ||

| Series “R” & “F”-CC, -EE, -LL, -MM, -LLL, -MMM, -PCC, -PEE, -PLL, -PMM (Multi-tank) with suffix “LC” |

424B | ||

| Series XF-LL, XF-PLL, XF-MM, XF-PMM, XF-EEE, XF-LLL, XF-MMM (Multi-tank) with suffix “LC” |

317B | 430B | |

| DD-8 | 318B | 430B | |

| Series R-L, R-PL, R-M, R-PM, F-L, F-PL, F-M, F-PM (single-tank) |

436B | 554B | |

| Series XF-L, XF-PL, XF-M, XF-PM (single tank) |

(2) 436B | — | |

| Series XF-PEE, XF-PLL, XF-PMM, XF-EEE, XF-LLL, XF-MMM (Multi-tank) |

545B | (2) 430B | |

| FA (Flight-A-Round) and RA (Rack-A-Round) use comparable “F” listing. |

– | – | |

| CHAMPION | UH1 | 306B | 309B |

| DH1, DH1C | 309B | 318B | |

| 44WS, 66WS | 315B | 427B | |

| PP28 | 427B | 545B | |

| 40KB, 44KB, 54KB, 60KB, 64KB |

436B | 554B | |

| UC-C | 545B | (2) 436B | |

| UC-CW (6 ft center max) |

554B | (2) 439B | |

| CHEMICAL METHODS ASSOC. | CMA-44H with tank heater |

424B | 545B |

| HOBART | LX-30 | 304B | |

| LX-18C, XL-30C, LX-40C, UM-4D, UMP-4D, WM-1D, WMP-1D, WM-5 |

304B | ||

| LX-18 | 305B | 309B | |

| WM-5C | 306B | 309B | |

| SM-6T2 | 306B | 312B | |

| WM-5 | 312B | ||

| AM-14T, AM-14F, AM-14TC | 309B | ||

| UM-4, UMP-4, WM-1, WMP-1 |

309B | 315B | |

| AM-12, AM-12C, AM-14, AM-14C |

309B | 312B | |

| C-44AW, CRS-66AW, CPW-80AW |

312B | 424B | |

| C-64W, CRS-86W, CPW-100W, C-88W, CRS-110W, CPW-124W |

424B | 436B | |

| FT800W | 424B | 439B | |

| C-64A, CRS-86A, CPW-100A, CMT-44 |

430B | 554B | |

| C-44, CRS-66, CPW-80, C-44A, CRS-66A, CPW-80A, C-88A, CRS-110A, CPW-124A |

436B | 554B | |

| C-64, CRS-86, CPW-100 | 545B | (2) 436B | |

| FT-600, FT-700, C-54, CRS-76, CPW-90 |

554B | (2) 439B | |

| FT-300 | 554B | (2) 545B | |

| FT800 | 439B | 554B | |

| FT800S, CRS-76A, CPW-90A, C-54A |

439B | (2) 436B | |

| UTW-28, UTW-28C | 318B | 436B | |

| INSINGER | Commander 18-3, 18-4, 18-4h, Ensign 40-2 |

306B | 312B |

| Trac 321, Trac 321-2/RPW | 318B | 430B | |

| Admiral 44-4, 66-4 | 424B | 436B | |

| Acmiral 44, 66-3 | 424B | 439B | |

| Speeder 7, 64, 86-3, Century 14 |

424B | 545B | |

| Master (all) | 436B | 554B | |

| Clipper (all) | 424B | 545B | |

| R106-2, Super 106-2 | 427B | 545B | |

| Defender | 436B | 554B | |

| JACKSON | JP-24, JP-24B, JP-24F, JP-24BF |

304B | 306B |

| 24B Series | — | 304B | |

| 10AB, 10APRB | — | 305B | |

| 44CE*, 66 CERPW | 430B | 554B | |

| 54CE, 76 CERPW | 436B | (2) 430B | |

| 64CE, 86 CERPW | 427B | 439B | |

| 100 | 312B | 424B | |

| 100B, 100PRB, 150B, 150PRB |

— | 309B | |

| 150 | 312B | 318B | |

| 200 | 312B | ||

| 200B | — | 306B | |

| Tempstar, Tempstar SDS |

306B | 312B | |

| AJ-44, AJ-66, AJ-80 | 424B | 545B | |

| AJ-54, AJ-76, AJ-90 | 436B | (2) 430B | |

| AJ-64, AJ-86, AJ-100 | 424B | 439B | |

| *Model #44CE w/SN1999 or below requires larger booster than listed. |

– | – | |

| KNIGHT EQUIPMENT (CANADA) LTD. | KLE-112-HL | 312B | |

| METALWASH/ INTEDGE |

FW4 | 312B | 318B |

| STERO | SF-1RA, SC20-1 | 312B | |

| SF-2RA, SF-2DRA, SD-2RA, SDRA, SDRA-PACK |

312B | 318B | |

| SCT-44, SCT-44-10, SCT-54, SCT-76S, SCT-76SC, SCT-76SM |

436B | 554B | |

| SCT-64, SCT-76, SCT-80, SCT-94, SCT-108, SCT-120, SCT-94S, SCT-108S, SCT-120S, SCT-94SC, SCT-108SC, SCT-120SC, SCT-94SM, SCT-120SM, SCT-150SM |

545B | 554B | |

| U-31-A | 436B | 554B | |

| U-31-A2, STPCW-5, STPCW-19, STPCW-19PS, STPCW-20, STPCW-22, STPCW-24 |

545B | (2) 436B | |

| STPCW-12PS, STPC-15S | 554B | (2) 554B | |

| STPC-12PS, STPC-15S | 554B | (2) 439B | |

| STPC-15, STPC-19, STPC-19S, STPC-20, STPC-22, STPC-24 |

436B | (2) 430B | |

| STBUW-14 | 554B | (2) 554B | |

| SC-2-4, SC-6-4, SC-1-2-3, SC-1-6-4, SC-5-6-4, SC-5-2-4 |

436B | 545B | |

| SC-2-3-4, SC-6-3-4, SC-2-7-4, SC-1-2-7-4, SC-1-6-3-4, SC-5-2-3-4, SC-1-6-7-4, SC-5-6-3-4, SC-5-2-7-4 |

430B | (2) 427B | |

| SC20-2 | 312B | 424B | |

| SC-2-8, SC-2-9, SC-1-2-8, SC-5-6-8, SC-6-8, SC-6-9, SC-1-6-8, SC-5-6-9, SC-5-2-9, SC-1-6-9, SC-5-2-8 |

318B | 436B | |

| VULCAN-HART | R16BTF, CU16BTF | 309B | 318B |

| 3D20TF, CD20TF | 312B | 424B | |

| A-64 Series, A-81 Series |

430B | 554B | |

| A44 Series, A54 Series, CP-2, CP-3, HP-3 |

545B | (2) 439B |

INNER TANK CONSTRUCTION

Standard horizontal booster inner tanks are constructed of stainless steel. Will not rust – 10 year warranty.

ELEMENTS

Heating elements are 1″ I.P.S., utilizing copper sheathing on hairpin rods to provide ultimate corrosion resistance, long life and efficient operation. All models specifying 480V to 600V are equipped with four flange mounted heating elements.

JACKET AND INSULATION

The outside shell is made out of sheet metal with a baked enamel finish and the front panel is made out of stainless steel. Two inches of fiber glass insulation surround the inner tank. Sturdy legs for floor mounting or stainless steel hanging supports for under counter suspension are available. (Specify when ordering.)

CONTROLS

A custom designed rapid response thermostat with adjusting dial switches a magnetic contactor which completes the power circuit to the heating elements. This electrical system is pre-wired on the right hand side of each booster, away from high ambient temperatures. A neon pilot light, mounted on the front, is wired to indicate that there is power to the heater and to show when the booster is operating. The unit includes a pre-wired electrical control panel complete with magnetic contactors, internal adjusting thermostat and pilot light.

PLUMBING INSTALLATION

- Locate booster as close to dishwasher as possible. Must be connected with copper tubing.

- Insure that incoming water is 140°F to pressure reducing valve furnished preset for 20 PSI.

- It is mandatory that a expansion tank and shock absorber be installed in the line between booster and dishwasher. (as close to dishwasher as possible)

- Install relief valve (furnished) on heater and plumb discharge in accordance with local codes.

- Install pressure temperature gauge in a tee on inlet between reducing valve and booster.

- Unions should be used in connecting the piping to the booster.

- It is recommended that the inlet and outlet lines be insulated to prevent heat loss.

- Check flow pressure with water flowing through the booster and, if necessary, readjust the pressure reducing valve to 20 PSI or to pressure recommended by dishwasher manufacturer.

ELECTRICAL INSTALLATION

- Ensure booster is full of water before turning on electricity. Elements will burn out immediately without water.

- Check booster data plate for correct amperage voltage and phase, and size supply wiring accordingly.

- Supply wires must be suitable to 75°C.

- A fused disconnect switch of at least 125% of the booster amperage rating must be installed between the power supply and the booster.

- Insure that plumber has installed booster with access to the elements and control panel.

- Set thermostat to give desired water temperature at dishwasher (usually 180°F).

- The pilot lamp indicates that power is on when booster heater is operating.

Service Bulletins

Warranty Cards

Remember that warranties are only valid if a warranty card is filled out and returned to Allied Technologies by the home owner. Online registration is available at our Product Registration Section of the website.