As of December 31, 2013 the AAE Commercial boiler is discontinued in favour of the new 85% AAA Commercial Boiler.

As of December 31, 2013 the AAE Commercial boiler is discontinued in favour of the new 85% AAA Commercial Boiler.

TURN UP THE HEAT ON THE COMPETITION AND COMPARE THE AAE COMMERCIAL BOILER

For Proven Perfomance and Fuel Efficiency

- AAE Series – Commercial, Industrial and Institutional Applications

Gas-Fired Hydronic Boilers – Natural Gas or Propane

19 Models Available for Optimum Sizing Flexibility

480,000 to 3,000,000 Btu/H Input

AAE 3000 Natural Gas c/w CSD-1 Gas train Assembly Flame Safeguard and Full Modulation Gas Valve (Control panel enclosure Removed for Display)

For more than sixty years, Allied Technologies has been an innovator in designing outstanding heating products, providing unparalleled customer service and excellent sales support. AAE Series boilers include all the innovations, efficiencies and technologies developed over these years making it one of the most dependable, energy efficient and long life boilers on the market today. Our development guidelines for quality, ease of operation, simple installation and low capital cost have been achieved.

- A true Two-Pass Flow Design

- Supply and Return can be connected to either side

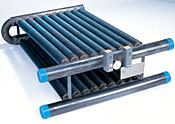

Burner Drawer Assembly with High Grade Stainless Steel Burners

Burner Drawer Assembly with High Grade Stainless Steel Burners

Features

STAINLESS STEEL ATMOSPHERIC BURNERS

High grade, heat resistant stainless steel ensures years of trouble free service, exceptional performance and improved fuel efficiency with virtually no combustion noise.

UNIQUE “DOUBLE PASS” STEEL FINNED TUBE HEAT EXCHANGER

Using the strength and durability of steel tube our team have greatly increased the heat transfer surface by continuously welding a spiral fin to each heat exchanger tube. These finned tubes are then welded to headers to form a top or bottom section. The two sections are welded using a 180º riser to complete the unique double pass heat exchanger design. This sturdy light weight design resists thermal shock and plugging of the heat exchanger due to large waterways provided by the 2″ OD ASME

(SA178A) boiler tube. In addition, the large waterways result in minimal pressure drop through the boiler and can reduce circulator cost. No other boiler combines these features to its advantage for strength rigidity, low cost and environmentally friendly construction.

RAPID RESPONSE TIME

A reasonable “medium mass” water content in conjunction with the exceptional heat transfer characteristics of the steel finned tube heat exchanger guarantees quick absorption of heat to the water flowing through it. When there is a call for heat you are assured of a rapid response to your heating requirements.

EASE OF INSTALLATION/OPERATION

Full assembled “AAE” boilers have a reputation for being simple to install and even simpler to operate and maintain. While we pride ourselves with this simplicity we also offer as options the very latest in sophisticated control systems and direct digital control terminal contacts. If necessary, the boiler can be easily dismantled and reassembled to allow passage through narrow aisles and doorways.

QUALITY CONSTRUCTION

AAE Series boilers are constructed to ASME section IV standards with a maximum working pressure of 160 psi (1100 kpa) and a maximum operating temperature of 240°F (115°C). Each is tested to 240 psi and certified by a third party inspector.

STANDARD EQUIPMENT

- Standing Pilot

- Intermitent Electronic Ignition

- Single Stage Gas Valve

- Two Stage Gas Valve

- Temperature/Pressure Gauge

- On/Off Switch with Indicator Light

- Operating Aquastat

- High Limit

- 30 psi A.S.M.E. Pressure Relief Valve

- 24 Volt Transformer and Fuse

- Draft Hood

- Natural Gas or Propane

- Control Panel Enclosure

OPTIONAL EQUIPMENT

- Low Water Cut Off

- Flow Switch

- Flame Supervision

- Indoor/Outdoor Control

- Redundant Gas Valve

- Alarm Feature

- Full Modulation Gas Valve

- Direct Digital Control Terminal Contacts

- Combination Seismic Restraint/Lifting Lugs

- Higher Pressure Relief Valves A.S.M.E.

- High/Low Gas Pressure Switches

QUALITY CONTROL

AAE Series boilers are manufactured to the American Society of Mechanical Technicians standards. Designed to A.S.M.E. Schedule IV with a maximum working pressure of 160 psi (1100 kpa) and a maximum operating temperature of 250ºF (120ºC). Each heat exchanger is tested to 240 psi to ensure leak

proof integrity of every boiler leaving the plant. Allied Technologies has a certificate of authorization for use the “U” stamp for pressure vessels and the “H” stamp for heating boilers

which is continually audited by A.S.M.E. and their authorized inspectors.

TEN YEAR LIMITED WARRANTY PROTECTION

Super Hot “AAE Series” boilers are manufactured under the highest standard of quality control, material and workmanship. Our proven design features a ten year warranty on the heat exchanger and one year on all parts and controls. See printed warranty for details. Installation, operating and maintenance instructions are supplied with every boiler.

ENVIRONMENT

Allied Technologies uses an environmentally friendly heat exchanger design that is designed for longevity and a minimum 80% efficiency. Most components are recyclable after their long, trouble free life.

Specifications

| MODEL NUMBER | INPUT | OUTPUT | DIM A | DIM B | DIM C | DIM D | |||||||

| MBH | kW | MBH | kW | H.P. | in | cm | in | cm | in | cm | in | cm | |

| AAE480 | 480 | 141 | 384 | 113 | 11.5 | 24 | 61 | 10.5 | 26.7 | 10 | 25.4 | 68.9 | 175 |

| AAE600 | 600 | 176 | 480 | 141 | 14.3 | 27 | 68.6 | 10.5 | 26.7 | 10 | 25.4 | 68.9 | 175 |

| AAE720 | 720 | 211 | 576 | 169 | 17.2 | 30 | 76.2 | 10.5 | 26.7 | 12 | 30.5 | 71.2 | 181 |

| AAE840 | 840 | 246 | 672 | 197 | 20.1 | 33 | 83.8 | 10.5 | 26.7 | 14 | 35.6 | 72.9 | 185.1 |

| AAE960 | 960 | 281 | 768 | 225 | 22.9 | 36 | 91.4 | 10.5 | 26.7 | 14 | 35.6 | 72.9 | 185.1 |

| AAE1080 | 1080 | 317 | 864 | 253 | 25.8 | 39 | 99 | 10.5 | 26.7 | 16 | 40.6 | 76 | 193 |

| AAE1200 | 1200 | 352 | 960 | 281 | 28.7 | 42 | 106.7 | 10.5 | 26.7 | 16 | 40.6 | 76 | 193 |

| AAE1320 | 1320 | 387 | 1056 | 310 | 31.5 | 45 | 114.3 | 10.5 | 26.7 | 18 | 45.7 | 77.3 | 196.3 |

| AAE1440 | 1440 | 422 | 1152 | 338 | 34.4 | 48 | 121.9 | 10.5 | 26.7 | 18 | 45.7 | 77.3 | 196.3 |

| AAE1560 | 1560 | 457 | 1248 | 366 | 37.3 | 51 | 129.5 | 10.5 | 26.7 | 18 | 45.7 | 77.3 | 196.3 |

| AAE1680 | 1680 | 492 | 1344 | 394 | 40.1 | 54 | 137.2 | 10.5 | 26.7 | 20 | 50.8 | 78.7 | 199.9 |

| AAE1800 | 1800 | 528 | 1440 | 422 | 43 | 57 | 144.8 | 10.5 | 26.7 | 22 | 55.9 | 80.7 | 205 |

| AAE1920 | 1920 | 563 | 1536 | 450 | 45.9 | 60 | 152.4 | 10.5 | 26.7 | 22 | 55.9 | 80.7 | 205 |

| AAE2040 | 2040 | 598 | 1632 | 478 | 48.7 | 63 | 160 | 10.5 | 26.7 | 24 | 61 | 82.6 | 209.8 |

| AAE2160 | 2160 | 634 | 1728 | 506 | 51.6 | 66 | 167.6 | 10.5 | 26.7 | 24 | 61 | 82.6 | 209.8 |

| AAE2280 | 2280 | 669 | 1824 | 535 | 54.5 | 69 | 175.2 | 10.5 | 26.7 | 24 | 61 | 82.6 | 209.8 |

| AAE2400 | 2400 | 703 | 1920 | 563 | 57.3 | 72 | 182.9 | 10.5 | 26.7 | 24 | 61 | 82.6 | 209.8 |

| AAE2520 | 2520 | 739 | 2016 | 591 | 60.2 | 75 | 190.5 | 12 | 30.5 | 2×18 | 2×45.7 | 78.8 | 200.2 |

| AAE2640 | 2640 | 774 | 2112 | 619 | 63.1 | 78 | 198.1 | 12 | 30.5 | 2×18 | 2×45.7 | 78.8 | 200.2 |

| AAE2760 | 2760 | 809 | 2208 | 647 | 65.9 | 81 | 205.7 | 12 | 30.5 | 2×18 | 2×45.7 | 78.8 | 200.2 |

| AAE2880 | 2880 | 845 | 2304 | 675 | 68.8 | 85 | 215.9 | 12 | 30.5 | 2×18 | 2×45.7 | 78.8 | 200.2 |

| AAE3000 | 3000 | 880 | 2400 | 703 | 71.7 | 87 | 221 | 12 | 30.5 | 2×18 | 2×45.7 | 78.8 | 200.2 |

| MODEL NUMBER | ** DIM E | * GAS CONN F | WATER CONTENT | SHIPPING WEIGHT | |||

| in | cm | NPT | US GAL | L | lb | Kg | |

| AAE480 | 12 | 30.5 | 1” | 5.56 | 21 | 675 | 307 |

| AAE600 | 13.5 | 34.3 | 1” | 6.75 | 25.5 | 725 | 330 |

| AAE720 | 15 | 38.1 | 1” | 7.95 | 30.1 | 790 | 359 |

| AAE840 | 16.5 | 41.9 | 1” | 9.14 | 34.6 | 860 | 391 |

| AAE960 | 18 | 45.7 | 1 1/4” | 10.34 | 39.1 | 940 | 427 |

| AAE1080 | 19.5 | 49.5 | 1 1/4” | 11.53 | 43.6 | 990 | 450 |

| AAE1200 | 21 | 53.3 | 1 1/4” | 12.73 | 48.2 | 1050 | 477 |

| AAE1320 | 22.5 | 57.2 | 1 1/4” | 13.92 | 52.7 | 1140 | 518 |

| AAE1440 | 24 | 61 | 1 1/4” | 15.12 | 57.2 | 1205 | 548 |

| AAE1560 | 25.5 | 64.8 | 1 1/4” | 16.31 | 61.7 | 1270 | 577 |

| AAE1680 | 27 | 68.6 | 1 1/2” | 17.51 | 66.3 | 1350 | 614 |

| AAE1800 | 28.5 | 72.4 | 1 1/2” | 18.7 | 70.8 | 1440 | 655 |

| AAE1920 | 30 | 76.2 | 1 1/2” | 19.9 | 75.3 | 1520 | 691 |

| AAE2040 | 31.5 | 80 | 1 1/2” | 21.09 | 79.8 | 1605 | 730 |

| AAE2160 | 33 | 83.8 | 1 1/2” | 22.28 | 84.3 | 1645 | 748 |

| AAE2280 | 34.5 | 87.6 | 1 1/2” | 23.48 | 88.9 | 1690 | 768 |

| AAE2400 | 36 | 91.4 | 1 1/2” | 24.67 | 93.4 | 1770 | 805 |

| AAE2520 | 2×18.25 | 2×46.4 | 2” | 25.87 | 97.9 | 1850 | 841 |

| AAE2640 | 2×19.75 | 2×50.2 | 2” | 27.06 | 102.4 | 1890 | 859 |

| AAE2760 | 2×20.25 | 2×51.4 | 2” | 28.26 | 107 | 1935 | 880 |

| AAE2880 | 2×21.00 | 2×53.3 | 2” | 29.45 | 111.5 | 1975 | 898 |

| AAE3000 | 2×21.75 | 2×55.3 | 2” | 30.65 | 116 | 2020 | 918 |

** AAE 2495 and larger use two draft hoods. Dimension “E” is measured from both left and right sides.

* Gas Connection “F” shows typical sizes only. Connections may vary depending on the gas valve used.

Derate Input/Output by 10% for Propane.

Flow Rate – Pressure Drop – Temperature Rise

| Input | Output | Δ10°F | Δ20°F | Δ30°F | Δ40°F | Δ50°F | Δ60°F | |||||||||

| btu | kW | btu | kW | GPM | FT.HD | GPM | FT.HD | GPM | FT.HD | GPM | FT.HD | GPM | FT.HD | GPM | FT.HD | |

| AAE480 | 480 | 141 | 384 | 113 | 77 | 11.9 | 38 | 3.0 | 26 | 1.4 | 19 | 0.8 | 15 | 0.5 | 13 | 0.3 |

| AAE600 | 600 | 176 | 480 | 141 | 96 | 11.2 | 48 | 2.8 | 32 | 1.3 | 24 | 0.7 | 19 | 0.5 | 16 | 0.3 |

| AAE720 | 720 | 211 | 576 | 169 | 115 | 11.7 | 58 | 3.0 | 38 | 1.3 | 29 | 0.8 | 23 | 0.5 | 19 | 0.3 |

| AAE840 | 840 | 246 | 672 | 197 | 134 | 10.6 | 67 | 2.7 | 45 | 1.2 | 34 | 0.7 | 27 | 0.4 | 22 | 0.3 |

| AAE960 | 960 | 281 | 768 | 225 | 153 | 11.9 | 77 | 3.0 | 51 | 1.3 | 38 | 0.8 | 31 | 0.5 | 26 | 0.3 |

| AAE1080 | 1080 | 317 | 864 | 253 | 173 | 12.1 | 86 | 3.4 | 58 | 1.4 | 43 | 0.8 | 35 | 0.5 | 29 | 0.3 |

| AAE1200 | 1200 | 352 | 960 | 281 | 192 | 12.3 | 96 | 3.1 | 64 | 1.4 | 48 | 0.8 | 38 | 0.5 | 32 | 0.4 |

| AAE1320 | 1320 | 387 | 1056 | 309 | 211 | 11.8 | 105 | 3.0 | 70 | 1.3 | 53 | 0.8 | 42 | 0.5 | 35 | 0.3 |

| AAE1440 | 1440 | 422 | 1152 | 338 | 230 | 11.7 | 115 | 3.0 | 77 | 1.3 | 58 | 0.7 | 46 | 0.5 | 38 | 0.3 |

| AAE1560 | 1560 | 457 | 1248 | 366 | 249 | 10.2 | 125 | 2.6 | 83 | 1.1 | 62 | 0.6 | 50 | 0.4 | 42 | 0.3 |

| AAE1680 | 1680 | 492 | 1344 | 394 | 268 | 11.3 | 134 | 2.9 | 89 | 1.3 | 67 | 0.7 | 54 | 0.5 | 45 | 0.3 |

| AAE1800 | 1800 | 528 | 1440 | 422 | 288 | 11.8 | 144 | 3.0 | 96 | 1.3 | 72 | 0.8 | 58 | 0.5 | 48 | 0.3 |

| AAE1920 | 1920 | 563 | 1536 | 450 | 307 | 11.6 | 153 | 2.9 | 102 | 1.3 | 77 | 0.7 | 61 | 0.5 | 41 | 0.3 |

| AAE2040 | 2040 | 598 | 1632 | 478 | 326 | 11.6 | 163 | 2.9 | 109 | 1.3 | 81 | 0.7 | 65 | 0.5 | 54 | 0.3 |

| AAE2280 | 2280 | 669 | 1824 | 535 | 364 | 15.8 | 182 | 3.9 | 121 | 1.7 | 91 | 1.0 | 73 | 0.6 | 61 | 0.4 |

| AAE2400 | 2400 | 703 | 1920 | 563 | 383 | 15.0 | 192 | 3.8 | 128 | 1.7 | 96 | 1.0 | 77 | 0.6 | 64 | 0.4 |

| AAE2495 | 2495 | 731 | 1996 | 585 | 403 | 14.6 | 201 | 3.7 | 134 | 1.7 | 101 | 0.9 | 81 | 0.6 | 67 | 0.4 |

| AAE2760 | 2760 | 809 | 2208 | 647 | 441 | 14.5 | 220 | 3.7 | 147 | 1.6 | 110 | 0.9 | 88 | 0.6 | 73 | 0.4 |

| AAE3000 | 3000 | 880 | 2400 | 703 | 479 | 14.4 | 240 | 3.6 | 160 | 1.6 | 120 | 0.9 | 96 | 0.6 | 80 | 0.4 |

Service Bulletins

AAE Series Commercial Gas Boilers Discontinued

This is to confirm that our AAE Series boilers will be discontinued as of December 31st, 2013 and replaced with our new 85% Energy Efficient AAA Series. The efficiency has been maximized for what can be achieved on a natural draft, atmospheric boiler before going into condensing mode while maintaining the overall proven design.

The AAA Series has the same foot print and venting as the AAE, except for the AAA600 model, which now has a 12” vent. This series is an ideal replacement for the commercial ‘A’ series, ‘AA’ series, and ‘AAE’ series of heating boilers. We are excited about the attractive new colour, optimal performance and long life durability – all at the most competitive prices.

For more details, please visit the AAA Commercial Boiler page or contact your local sales representative.

Warranty Cards

Remember that warranties are only valid if a warranty card is filled out and returned to Allied Technologies by the home owner. Online registration is available at our Product Registration Section of the website.